THE VERSATILE USES OF DRY ICE

Traditional methods like sandblasting have long been the go-to choice when it comes to industrial cleaning and surface preparation. However, recent advancements have introduced a more efficient and eco-friendly alternative known as dry ice blasting. Quickly becoming a popular alternative to sandblasting, blasting with dry ice is a complete dry process that greatly reduces the chance for damage during the cleaning process, while also decreasing the downtime of production equipment being taken out of service for routine cleanings.

Unveiling the Magic of Dry Ice Blasting

What is Dry Ice Blasting?

Dry ice blasting, also referred to as CO2 blasting, is a non-abrasive cleaning method that uses solid carbon dioxide (CO2) pellets propelled at high speeds to clean and prepare surfaces. The process involves accelerating the dry ice pellets through specialized equipment, which transforms them into a high-velocity stream of CO2 snow upon impact with the surface. As the dry ice particles strike the targeted material, they rapidly sublimate, converting from a solid state directly into a gas, leaving no residue behind.

Benefits of Dry Ice Blasting:

- Non-abrasive: Unlike sandblasting, which uses abrasive materials that can damage delicate surfaces, dry ice blasting is non-abrasive and gentle on the substrate being cleaned. This makes it suitable for a wide range of materials, including plastics, metals, wood, and more.

- Environmentally friendly: Dry ice blasting is a sustainable and eco-friendly cleaning method. It does not produce any secondary waste, as the dry ice pellets sublimate into the atmosphere, leaving no chemical residues or pollutants behind. It does not require the use of harmful chemicals or solvents, making it safe for both operators and the environment.

- Non-conductive and non-toxic: Dry ice blasting is a safe option for electrical and sensitive equipment, as the dry ice pellets are non-conductive. It also eliminates the need for harsh chemicals, making it a non-toxic cleaning solution.

Versatile Uses for Dry Ice Blasting

Industrial Cleaning Applications:

- Manufacturing: It effectively removes paint, grease, oils, and adhesives from equipment, molds, and production lines.

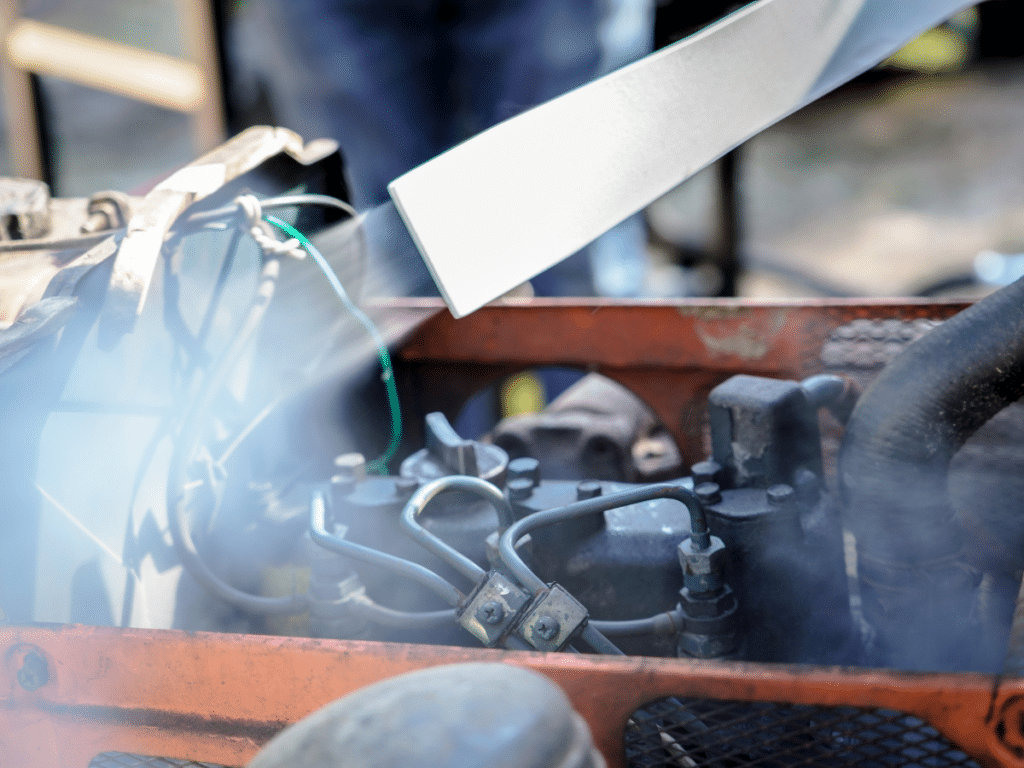

- Automotive: Dry ice blasting is used for cleaning engines, removing wax and undercoating, and degreasing automotive parts.

- Food Processing: It is utilized for removing carbonized residues, cleaning ovens, freezers, conveyors, and other equipment in the food industry.

- Restoration: Dry ice blasting can safely and efficiently remove soot, mold, and other contaminants from fire-damaged buildings and artifacts.

- Electronics: It aids in the removal of flux, resins, and contaminants from delicate electronic components and circuit boards.

Advantages over Sandblasting

- No media cleanup: Unlike sandblasting, which produces massive amounts of debris that require cleanup, dry ice blasting eliminates the need for media collection, reducing downtime and increasing productivity.

- Reduced equipment wear: The non-abrasive nature of dry ice blasting means less wear and tear on equipment, resulting in lower maintenance costs and longer equipment lifespan.

- No damage to substrates: Dry ice blasting is gentle on surfaces, ensuring minimal damage to the substrate being cleaned. It does not warp or etch the material, maintaining its integrity and quality.

- Precision cleaning: Dry ice blasting allows for precise and targeted cleaning. The adjustable pressure and pellet size make it suitable for a wide range of applications, from delicate electronics to heavy industrial machinery.

- Time and cost-effective: Dry ice blasting reduces cleaning time and increases efficiency. It eliminates the need for disassembly and reassembly of equipment, resulting in reduced downtime. The absence of secondary waste disposal and reduced labor costs contribute to overall cost savings.

Dry ice blasting has revolutionized the field of industrial cleaning and surface preparation. Its non-abrasive nature, eco-friendliness, and versatility make it a preferred alternative to traditional methods like sandblasting. With its ability to remove contaminants effectively, safely, and efficiently from a wide range of materials and surfaces, dry ice blasting is becoming the go-to solution for various industries.

If you’re looking for a powerful, eco-friendly, and efficient cleaning method, it’s time to explore the magic of dry ice blasting with a call to General Abrasives. Providing clients with a cumulative 30 years of experience, we utilize cutting edge technology and experience to remove paint or product build-up and contaminants that keep your equipment from operating properly and helps to prevent unplanned production stoppages and costly repairs.