PACKAGING & PRINTING CLEANING

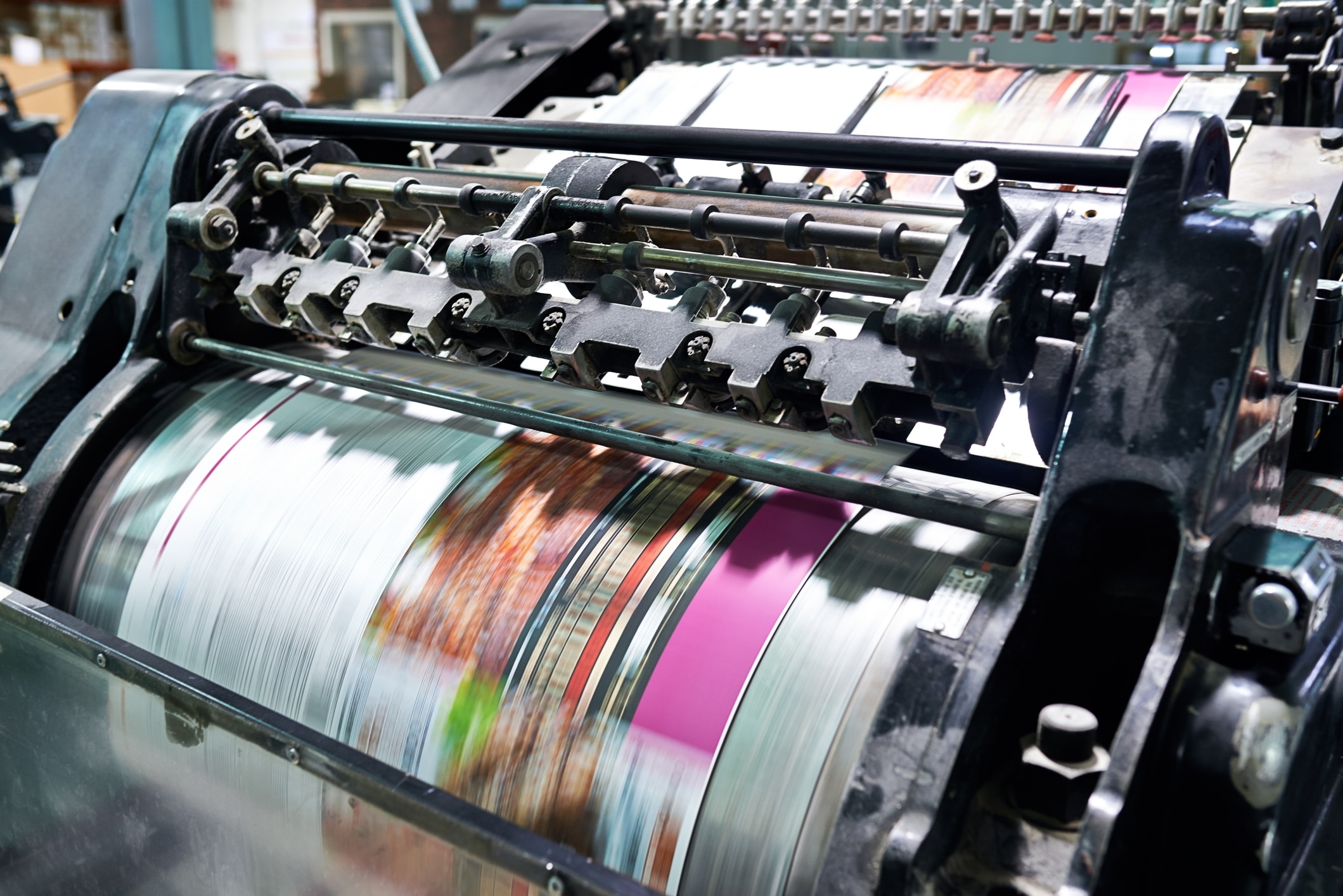

Cleaning printing and packaging equipment with the use of dry ice blasting, General Abrasives Co. Inc can remove ink, grease, paper lint, and other built up coatings from a variety of equipment types. Providing non-abrasive cleaning solutions for the printing industry, dry ice blasting minimizes downtime and increases production time at your facility.

Using a variable pressurized air stream with dry ice pellets, the dry ice creates fractures in the contaminants, breaking apart the surface and allowing for easy removal, without leaving behind any secondary waste or residue. General Abrasives provides customized printing equipment cleaning services, a valuable alternative to sandblasting or abrasive cleaning methods for many products.

BENEFITS OF DRY ICE BLASTING FOR PACKAGING & PRINTING

With adjustable streams and PSIs ranging from ranging from 60 to 250 PSI, our equipment allows us to service a wide range of products with one application. Versus traditional cleaning methods, including sand blasting, water blasting, soda blasting, hand cleaning, or solvents and chemicals, dry ice blasting is non-conductive and non-abrasive, in addition to being non-toxic and producing no secondary waste.

Key Benefits:

COMMON APPLICATIONS OF DRY ICE BLASTING

Ideal for cleaning dried ink on ink trays and printer heads and press rollers, dry ice blasting offers a viable solution for cleaning coating types that are not soluble once dried. With dry ice blasting, the pressurized stream of dry ice pellets is able to clean in nooks and crannies of all sizes, without the equipment having to be taken out of service or disassembled. An environmentally responsible cleaning, dry ice blasting produces no harmful secondary waste and does not produce any harmful gases.

Types of Equipment:

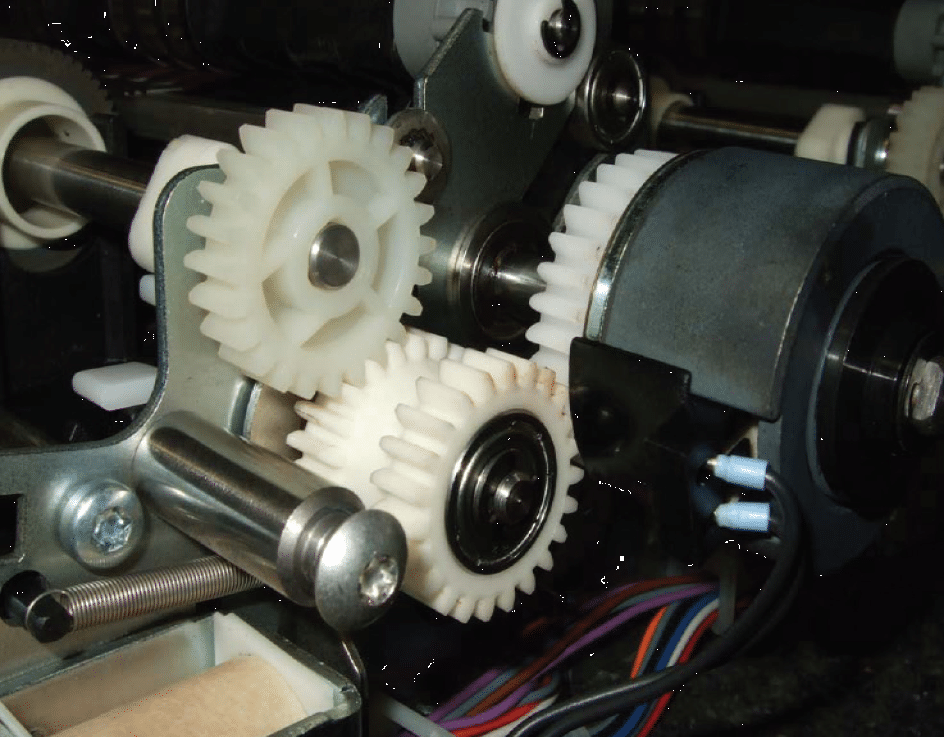

There are many types of printing press assemblies, from flexography, offset and web-fed that are made up of many components. Taking them offline and allowing cool-down and disassembly for cleaning is a very time consuming process and takes away from production. With dry ice blasting, cleaning can be accomplished in-place, eliminating the need for disassembly and taking equipment offline. Since this is a waterless cleaning method, you are not in danger of damaging electronic components nor do you have to wait for equipment to dry before resuming operations.

The versatility provided by dry ice blasting can be incorporated into both printing press and as well as packaging equipment cleaning, providing general cleaning applications as well as specialized remediation and heavy-duty cleaning services. Superior over the labor and time intensive option of hand cleaning or potentially damaging chemical strippers, a main benefit of dry ice is the added efficiency into your production or cleaning processes.

HOW IT WORKS

Using pressure blasted particles of solid carbon dioxide (commonly called dry ice), instead of using small, abrasive particles for blasting, dry ice blasting uses a pressurized stream of dry ice pellets that are initially solid and begin to sublimate (instantaneously turn to gas) upon impact. Surface coatings like paint, oil, adhesives, and accumulated debris shrink from the change in temperatures and are forcibly blown off the surfaces they are attached to, leaving a clean, dry substrate. This is especially effective in environments where pollution and dust are detrimental to the system’s operation.

WORK WITH GENERAL ABRASIVES

Offering a cumulative 30 years of experience and knowledge, General Abrasives is local to South Louisiana and a proud part of the community, keeping equipment clean and helping to divert unexpected shutdowns. When used as preventative maintenance as well as during inspection processes, dry ice blasting allows you to take advantage of it’s quick services to reduce production downtime and unplanned maintenance. Contact our team today to learn more.