Three Everyday Uses: Restoration with Dry Ice Blasting

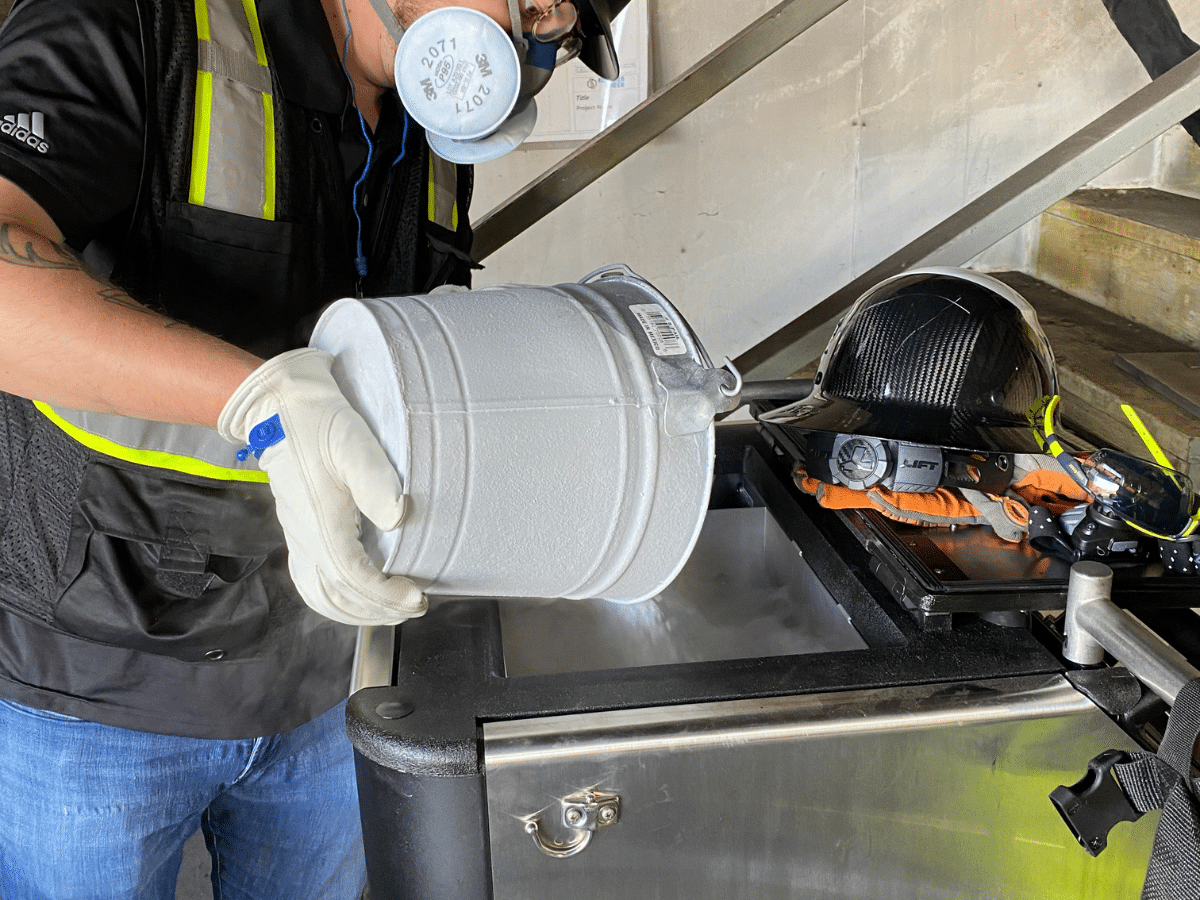

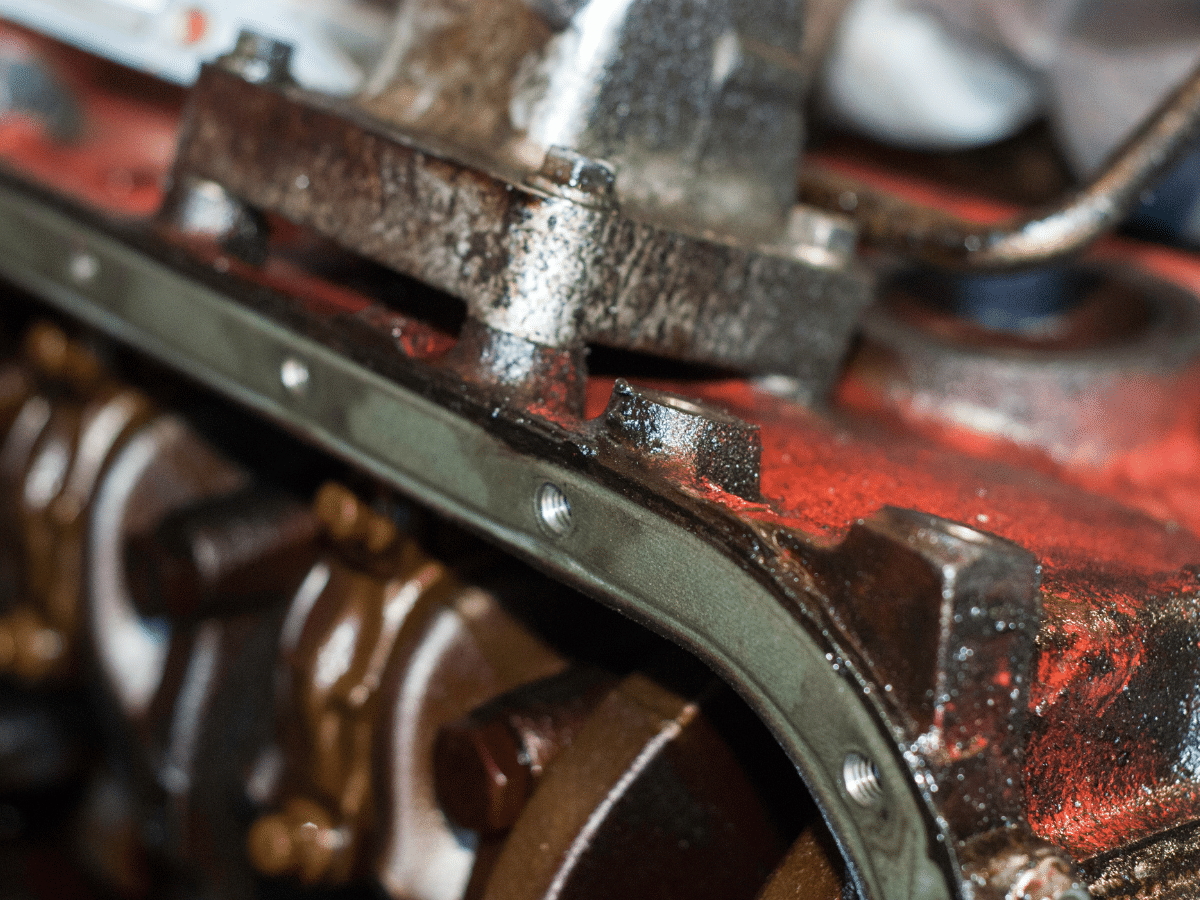

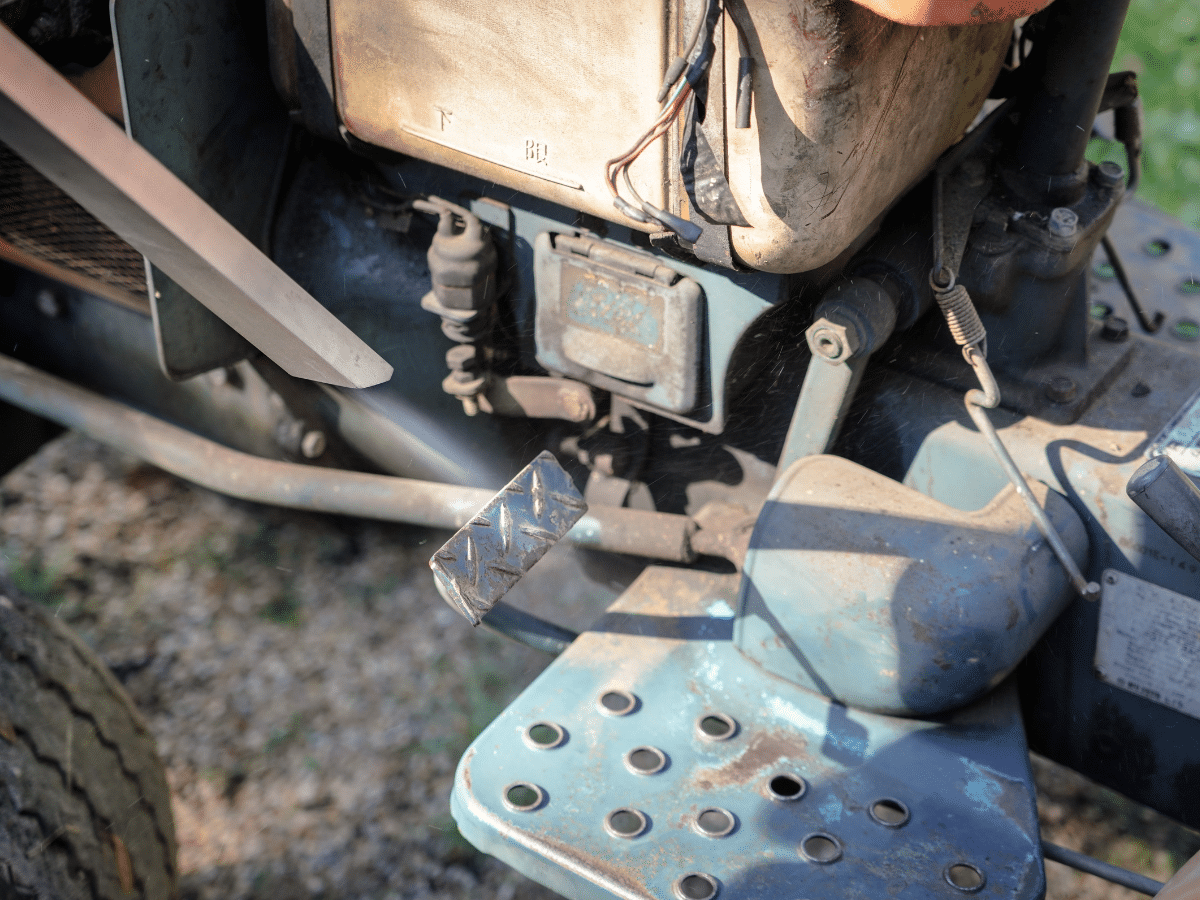

Restoration projects are a delicate balance between reviving the past and preserving the present. Whether you're revamping classic cars, restoring antique furniture, or recovering from fire damage, the key lies in choosing the right method.