THE POWER OF DRY ICE

These days, industries are seeking innovative solutions to reduce their ecological footprint. One such groundbreaking technology that has emerged is dry ice cleaning. While questions might arise about its impact on the environment, the truth is, dry ice cleaning offers a range of benefits that make it a sustainable choice for businesses looking to clean effectively without harming the planet.

Is Dry Ice Bad for the Environment? Dispelling the Myth

The term “dry ice” might conjure thoughts of carbon emissions and environmental harm, but this couldn’t be further from the truth. Dry ice cleaning involves the use of solid carbon dioxide (CO2) pellets to clean surfaces. Unlike traditional cleaning methods that utilize harmful chemicals and produce waste, dry ice cleaning relies on the sublimation process—solid CO2 transforming directly into gas upon contact with a surface. This means there are no leftover residues or waste materials to manage.

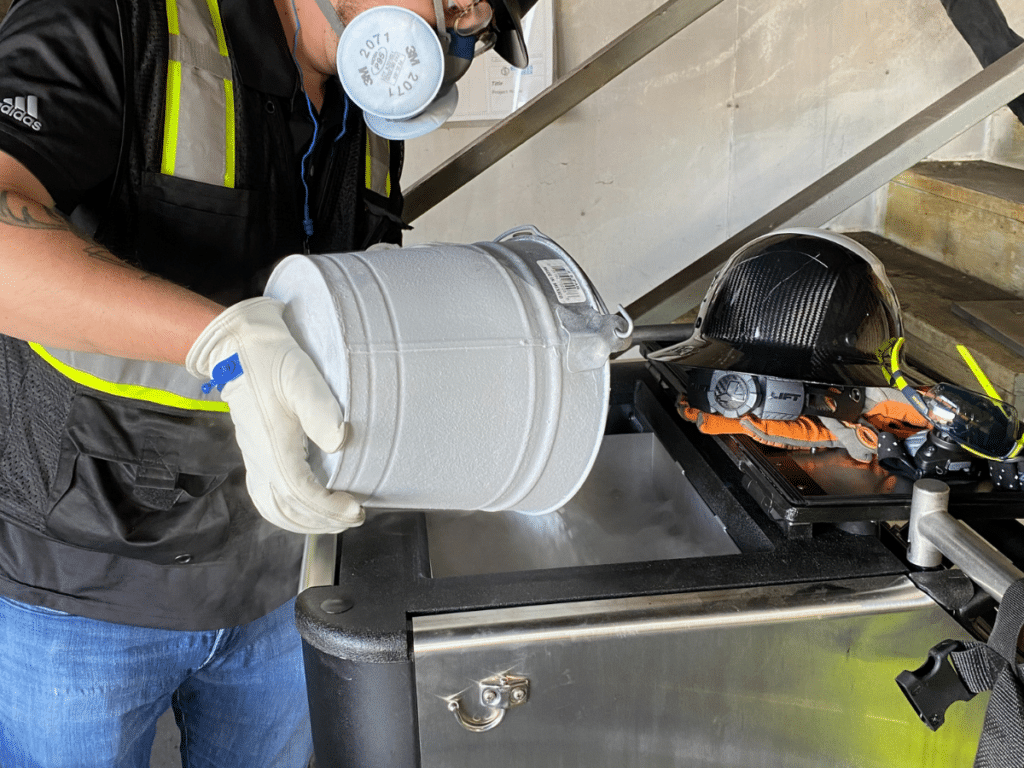

Dry ice pellets, the heart of this cleaning method, are created by pressurizing and cooling liquid CO2, resulting in tiny, high-velocity pellets. These pellets become powerful cleaning agents due to their unique properties. They are non-abrasive and do not produce secondary waste, making them ideal for delicate surfaces and intricate machinery. Additionally, since the pellets dissipate into the atmosphere as CO2 gas, they don’t contribute to additional greenhouse gas emissions.

Embracing Environmentally Safe Cleaning Products

Traditional cleaning methods often involve the use of chemicals that can harm both the environment and human health. These chemicals may seep into the soil and water systems, leading to long-term damage. Dry ice cleaning, on the other hand, completely eliminates the need for chemical solvents and detergents, safeguarding both the environment and the health of workers.

Reducing Water Usage: Water scarcity is a growing concern globally. Many conventional cleaning methods rely heavily on water, contributing to the depletion of this precious resource. Dry ice cleaning, however, is a waterless process. As its name suggests, it uses dry ice pellets, which means that no water is required during the cleaning process. This not only reduces the strain on water supplies but also prevents the release of contaminated wastewater back into the environment.

Energy Efficiency and Carbon Footprint Reduction: Energy consumption is another significant factor in evaluating the environmental impact of a cleaning method. Traditional cleaning techniques often involve high-energy processes such as heating water or running large equipment. Dry ice cleaning, while requiring electricity to power the cleaning equipment, is still more energy-efficient compared to many other methods. The production of dry ice pellets also requires less energy than the manufacturing of chemical cleaning agents.

The Versatility of Dry Ice Cleaning: One of the most compelling aspects of dry ice cleaning is its versatility. It can be used across various industries, from manufacturing and automotive to food production and historical preservation. This adaptability not only reduces the need for specialized cleaning methods but also ensures that the benefits of dry ice cleaning can be enjoyed by a wide range of businesses, regardless of their field.

In the ongoing pursuit of a cleaner and greener future, businesses are called to adopt practices that prioritize sustainability without compromising efficiency. As industries continue to evolve and adapt to eco-friendly practices, the choice is clear—dry ice cleaning not only gets the job done but does so while treading lightly on the Earth. With General Abrasives, let’s embrace the power of dry ice cleaning and pave the way for a more sustainable tomorrow.