If you’re reading this article, chances are you’ve wondered whether sandblasting or dry ice blasting is right for you. We’re here to help you understand the pros and cons of the various solutions and decide for yourself what is best for your situation.

In this article, we’ll unpack the advantages and disadvantages of sandblasting and dry ice blasting, as well as the best times to use each of them.

Where Can I Use Sandblasting?

Though it’s called “sandblasting,” there are actually several abrasives to choose from. Some of the most common choices are sand, concrete, soda, glass, and metal. Sandblasting can be a great solution when you need a powerful method to strip off stubborn layers like paint, corrosion, and oil-stained concrete.

However, because sandblasting uses abrasive media, its power comes at a cost. It can profile surfaces, meaning it can wear down the surface you blast with it. If you’re cleaning concrete or blasting away a stubborn coating, this can be advantageous. Just be sure to take that into account when deciding if sandblasting is right for you, so you don’t damage or wear down whatever you blast.

Additionally, because sandblasting necessitates blasting with small particles, it requires specialized equipment in order to mitigate potential health hazards. Depending on the application, sand particles or other media remains can get caught in crevices of machinery, posing challenges after the blasting process is complete. Because of this, sandblasting can be a good solution for blasting individual parts and buildings, but may not be the best fit for complex machinery.

Where Can I Use Dry Ice Blasting?

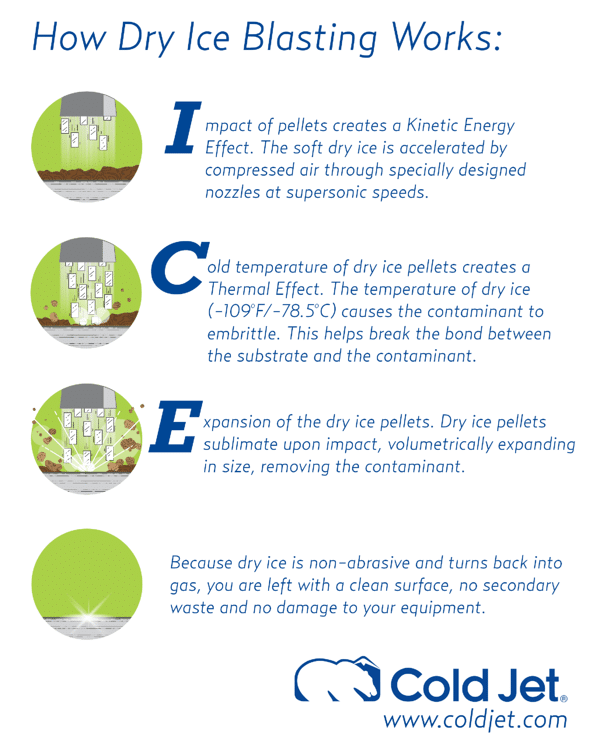

Dry ice blasting has many similarities to sandblasting, but is distinct in several key ways. Dry ice blasting, while less aggressive, is also not abrasive. Instead of using small, solid particles for blasting, dry ice blasting uses pellets of C02 that start solid and sublimate – or, instantaneously turn into gas – upon impact.

With dry ice blasting, impact, ultra-cold temperatures, and expansion during sublimation work together to embrittle and remove dirt, rust, and other unwanted contaminants – without profiling or altering the underlying surface. Another added benefit is that dry ice blasting doesn’t leave behind any secondary residue: no liquid and no micro-particles.

However, as previously mentioned, dry ice blasting is less aggressive than sandblasting because it doesn’t rely solely upon impact to get the job done. Although, if you’re looking for a happy medium, the E-CO2 150 combines dry ice blasting with an abrasive medium, allowing for a strong degree of versatility.

Which is Right for Me?

Hopefully this article has given you some useful insights to help you decide which solution is best for you. If your problem requires some heavy-duty blasting, and you don’t mind the additional setup and cleanup, sandblasting might be a good solution. For precision, speed, simpler setup/blasting process, and assurance that you won’t damage the surface you blast, you may want to consider dry ice blasting.

What’s Next?

If you’re considering dry ice blasting or have any questions, get in contact with us and let us know how we can help.